- Services -

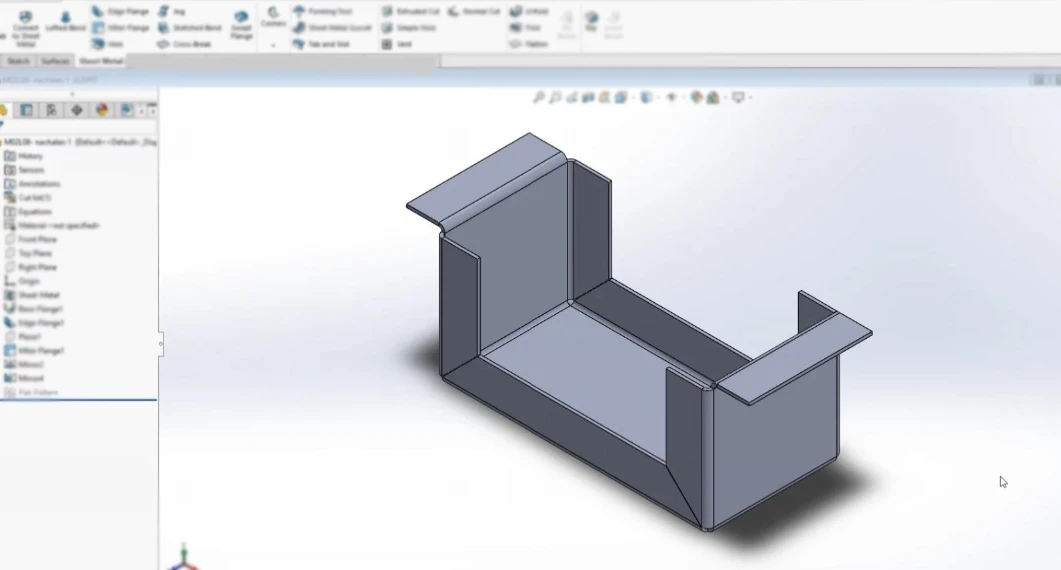

Design

We can prepare a project to visualize the wanted products from you in the best way.

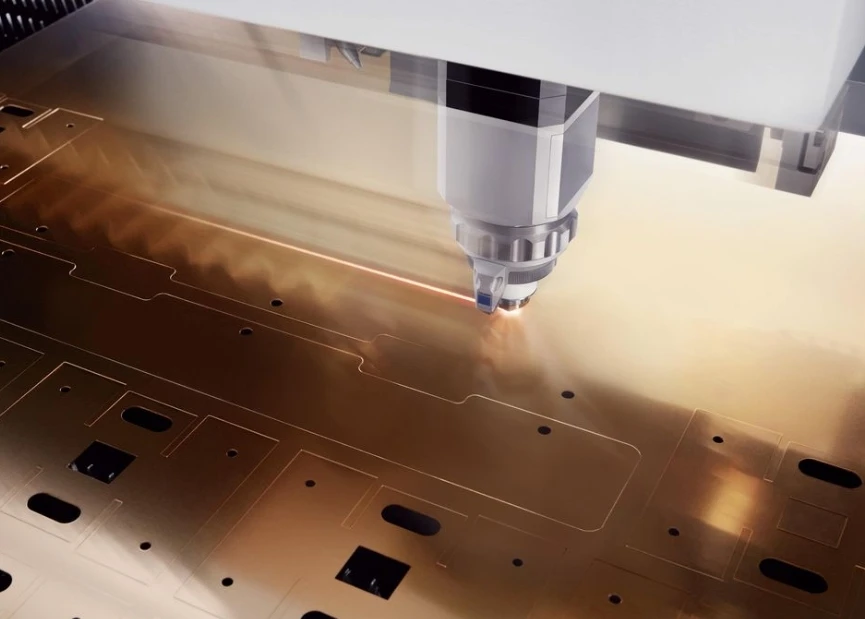

Laser cutting

We work with the newest generation fiber and CO2 lasers. We can also cut ferocious steel – up to 20 mm in thickness, stainless steel – 10 mm, aluminium – 15 mm .

Size of the tables of the machines - 1500х3000 mm.

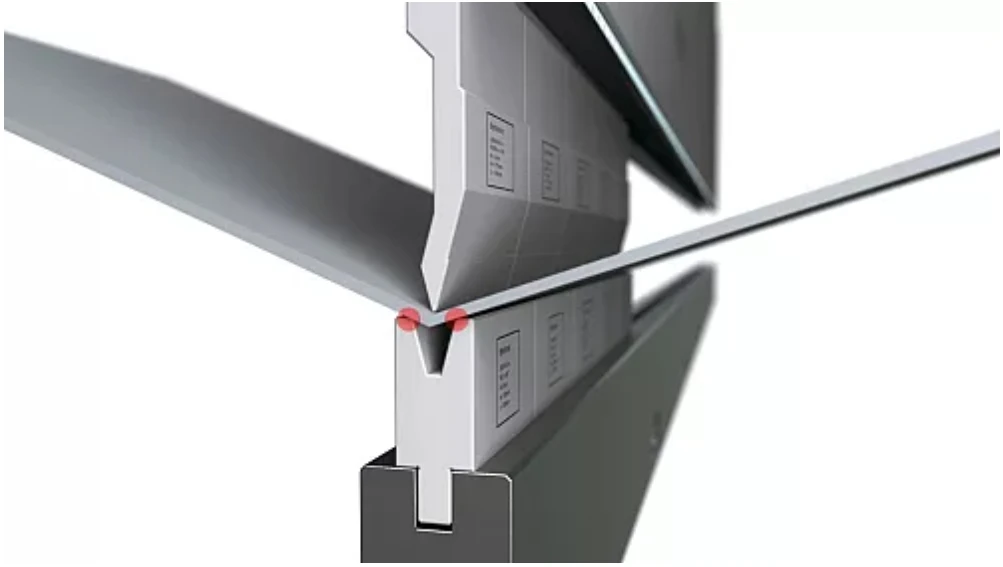

Bending

With the process of bending we can make the wanted form of a product or an assembled one. We have the newest generation CNC press brakes with maximum length of bending 2500 mm and pressure up to 100 tons.

If you already have a project in dwg or dxf format we can complete it.

Metal bending by Hydraulic presses

Apart from the aforementioned press brakes we can also bend with the available 8 hydraulic presses in our factory.

Their pressure can be from 3 to 25 tons and they are also an extremely good option for large series of details.

Welding

We have all necessary machines for welding of thin metal elements, stainless and aluminum products.

To reach the final look, every product goes through grinding, welding and cleaning the welding traces, after which it is ready for the final coat.

Powder coating

The final vision of most of the products, which are made of carbon/black steel is achieved through applying powder steel and baking in a special oven.

In this way your product is already shining in the wanted color and protected for a very long time.

Installation of self clinching fasteners

Merian LTD company is specialized in crimping fasteners of any shape.

We have automatic machines, which prepare the fasteners in the work area. In this way we guarantee constant quality and fast execution of the details.

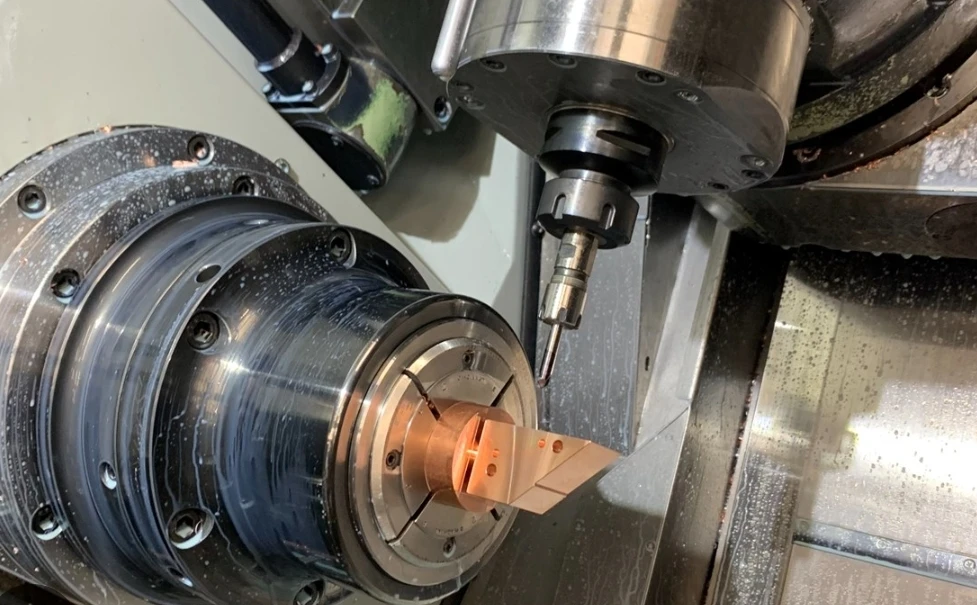

Details produced on CNC turning mashines

There are available CNC turning machines, thanks to which we can produce precise products with complex geometry.